Creating a flowchart of the process. Creating a flowchart of the process.

The Current State Of Acme With Traditional Value Stream Mapping Download Scientific Diagram

Is a variation on time function mapping b.

. The value stream map is formed through collaboration crossing functions in the name of what delivers customer value. All of these are true. Value-stream mapping differs from time-function mapping by A.

Each value stream is a long-lived series of steps used to create value. Value stream mapping VSM is a graphical tool originally used in the auto industry to define a method for streamlining work processes called lean manufacturing Toyota is credited with defining this strategy of steps that has led to a standard known as Six Sigma. The correct answer is option B Value-stream mapping is a variation of time-function mapping.

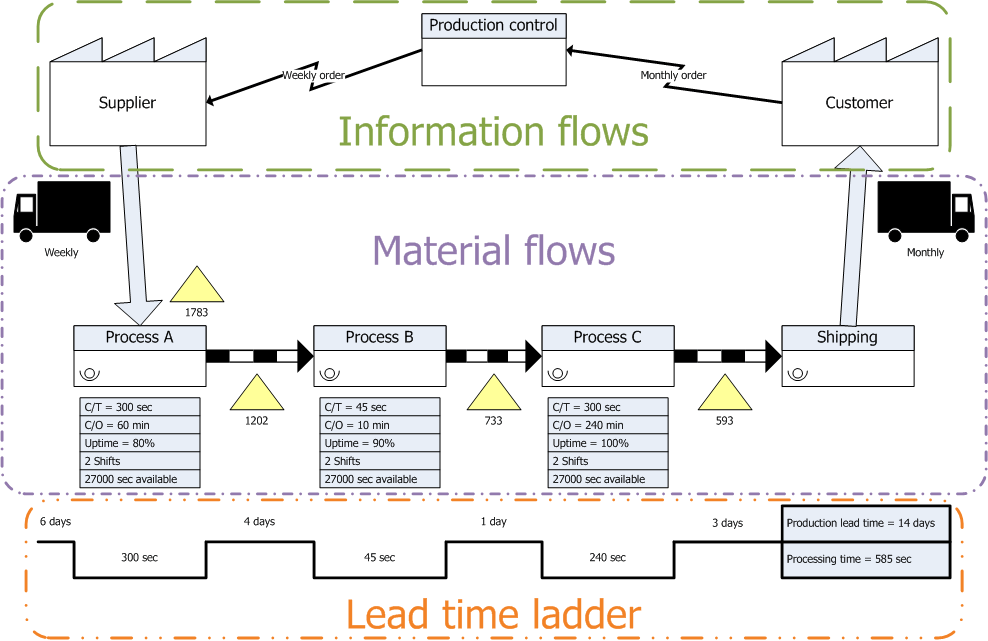

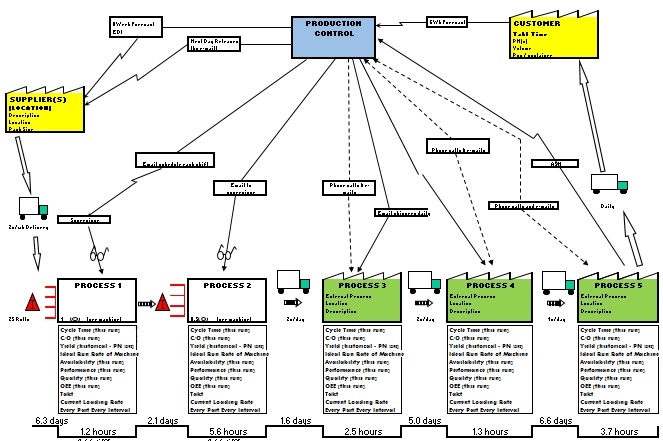

SAFe defines two types of value streams as shown in Figure 2. Shows flows and time and value added beyond the immediate organization. Enabling culture change within an organization.

This mapping shows the areas in a process where values are added or not added so as to bring the productivity in the process. The value stream mapping is refereed to as the variation of time-function mapping. Examines the supply chain to determine where value is added c.

Perhaps the simplest way of looking. Heres a comparison between these two mapping tools. Process maps as well will often involve great detail and therefore take a longer time to formulate visually whereas the value stream map will involve multiple parties building out the view of the work flow therefore taking less time to create.

Extending the analysis back to suppliers. Extended Value Stream Maps take an even broader view and often. Examines the supply chain to determine where value is added.

Extending the analysis back to suppliers. Simply put a value stream is a series of steps that occur to provide the product or service that their customers want or need. Creating a flowchart of the process.

Many lean practitioners see VSM as a fundamental tool to identify waste reduce process cycle times and implement. The various icons and symbols have fairly specific meanings and it requires knowledge of these symbols as well as knowledge of TPS to interpret a Value Stream Map and use it well. The steps in the middle are the activities used to develop or deliver the value.

Extends time function mapping back to the supplier. Starts with the customer and works backwards. Value-stream mapping differs from time-function mapping by.

Starts with the customer and works backwards e. What is Value Stream Mapping VSM Benefits Process and Value Reading time 10 minutes. A trigger starts the flow of value and theres some form of monetization or value delivered at the end.

Examines the supply chain to determine where value is added c. Extends time function mapping back to the supplier d. Starting with customers and understanding the production process.

Starts with the customer and works backwards e. Different industries on the slides but for example-Financial services - Debit cars ATMs internet stock trading. Starting with customers and understanding the production process.

The difference between value stream mapping and process mapping is that VSM offers a birds eye view while process mapping offers a more detailed view. In other words value stream maps VSM are ideal to evaluate major functions within. Youd use a value stream map to identify major tasks to improve a business function.

Extending the analysis back to suppliers. Extending the analysis back to suppliers. E Process analysis and design moderate e.

Value-stream mapping differs from time-function mapping by A. To understand value stream mapping we need to first understand what a value stream is. Value Stream Mapping a.

On the other hand process mapping provides a more detailed picture of the business process. Extends time function mapping back to the supplier d. Starting with customers and understanding the production process.

Youd use process mapping to delineate the exact steps to take a single task from beginning to completion. Process mapping as the name implies examines individual processes and ways they can be made more efficient while value stream mapping takes a more holistic view looking at the wider business picture. While both tools can be used for mapping when it comes to their applications the resemblance ends there.

Value stream mapping VSM is defined as a lean tool that employs a flowchart documenting every step in the process. - extention of time function mapping - starts from customer and works all the way back to the supplier. Creating a flowchart of the process.

Encouraging continuous improvement of a process. 1 More from Creating Flow. Creating visualizations of delays excess inventory and production constraints.

With this in mind combining value stream management and value stream mapping can produce great results to help you drive your organization forward. Operations Management questions and answers. Is a variation of time-function mapping.

All of the above are true. Is a variation on time function mapping b. Value Stream Mapping a.

Process mapping tracks and analyzes the steps in a process looks at the sequence of steps and eliminates those not needed or reorders steps for better efficiency. 5212019 Value stream mapping is a graphical tool originally used in the auto industry to define a method for streamlining work processes called lean manufacturing. Value Stream Maps reflect a broad view of the process usually from external supplier to external customer at a given facility.

When considering process views VSM offers a broader or 360-degree view of the business process. Differences Between Value Stream Mapping Process Mapping. The purpose of value stream mapping is to maximize value and minimize waste in a number of different ways including.

Value-stream mapping differs from time-function mapping by A. Starting with customers and understanding the production process. Facilitating clear communication and collaboration.

All of the above are true. Value stream analysis lean process mapping.

Value Stream Mapping Definition Steps And Examples Tallyfy

Value Stream Mapping Vsm Process Mapping Value Stream Map Symbols

Misconceptions About Value Stream Map

Value Stream Mapping For Recruitment Process And Application Of Lean Process Improvement Techniques Wordofprint

0 Comments